Pre-inspection

Photography and pre-inspection are common to all washed and dry cleaned products.

photo shoot

First, all products take pictures in advance. In addition to the whole, points to be noted and damaged parts will be expanded and expanded, and will be used for comparison in advance. At this stage, determine the way of washing and sort.

Inspection

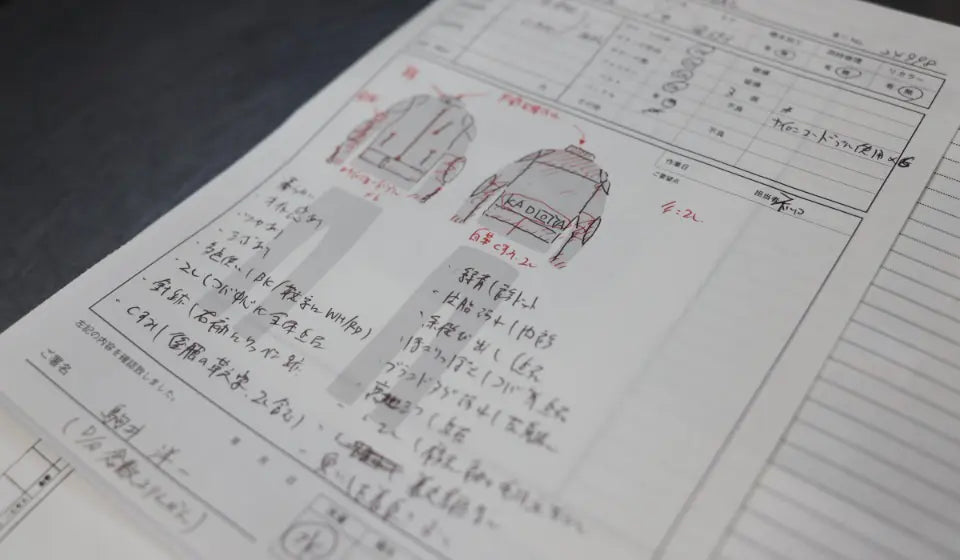

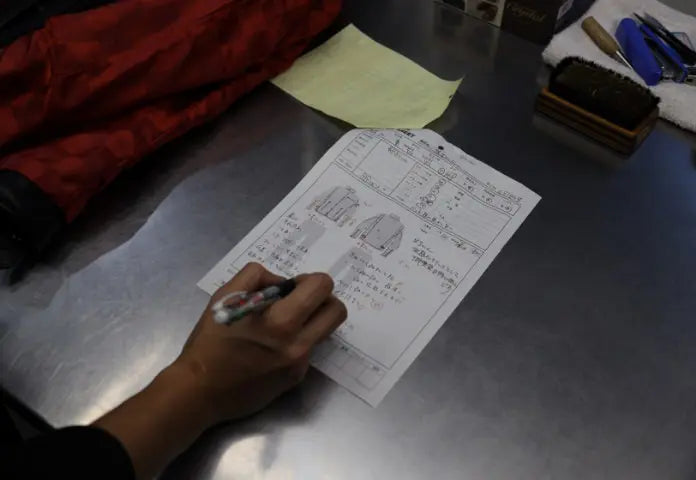

We also perform a detailed inspection to check for dirt, scratches, and odors, and record them on the checklist. In addition to the leather, we also record details such as the lining, pocket contents, and the presence or absence of accessories.

Water cleaning procedure

Cleaning with water is suitable for items that are bothersome to smell, leather jackets with mold or water-soluble stains, and leathers that are likely to change color when dry cleaned, such as oiled leather. Water cleaning is a unique cleaning method that is divided into two main stages: washing and nourishment.

STEP ①

Preprocessing

Use an airbrush to remove lint and dust that has accumulated in pockets etc. beforehand. Remove mold and mud stains by wiping or washing with water before washing.

To prevent scratches on your favorite leather products, we mask and protect metal parts such as belt buckles and large zippers.

STEP ②

Washing with water

Using several types of brushes and sponges, we hand wash even the smallest details such as stitches, zippers, and shirring.

The use of detergents with different removal powers and the level of brushing force are extremely delicate tasks, as the craftsman must judge the condition of the leather and the type of dirt.

After hand-washing, by briefly agitating and removing liquid in the washing tub, the clear solution in the washing tub turns brown and the musty odor disappears from the leather jacket.

STEP ③

Nutrition Supply

It is soaked in a special conditioner solvent to provide nutrients. The pickling time will be determined by the craftsman depending on the color, leather quality, and condition.

Personal care involves simply applying oil to the surface of the leather, but it is possible to fill it with moisturizing ingredients by slowly penetrating the leather with nutrients from both the front and back.

STEP ④

drying

To prevent it from losing its shape during drying, make sure it is shaped well before drying. We also have know-how on how to dry clothes to prevent them from losing their shape.

Of course, the time required for drying varies depending on the product. For example, if you have a leather jacket, dry it naturally for about 7 to 10 days.

Dry cleaning instructions

Cleaning with water is suitable for items that are bothersome to smell, leather jackets with mold or water-soluble stains, and leathers that are likely to change color when dry cleaned, such as oiled leather. Water cleaning is a unique cleaning method that is divided into two main stages: washing and nourishment.

STEP ①

Preprocessing

Similar to washing with water, after removing large stains with an airbrush, apply a preparation agent to the areas where the stains have adhered. We use a preparation agent suitable for oil-based stains and one suitable for water-based stains, and use different brushes to perform preparations on even the smallest of areas. The know-how of craftsmen comes into play in this groundwork treatment.

STEP ②

wash

The leather jacket that has been pre-processed is put into the drying machine. The washing time is determined based on the condition of dirt, leather quality, etc.

After a few minutes of washing, a lengthy dehydration process takes place inside the machine. Nourishing is also completed at this stage as the solvent contains conditioner.

STEP ③

drying

Because tumbling takes a long time, the metal parts are masked more strictly than washing them, and they are placed in a special net to prevent them from losing their shape.

Dry slowly and carefully in a rotating drum at medium temperature. After the drum drying is complete, it is arranged to prevent it from losing its shape and then air-dried. The drying time will also vary depending on the product, but the jacket will take about 10 to 14 days to fully remove the solvent.

surface treatment

``The tanning fat inside the leather has completely disappeared (cracks, tears, peeling of the silver surface, hardening, atrophy, etc.)'', ``The stitching has deteriorated significantly (frayed, torn, breaks with just a light tug, etc.)'' '', ``Dye fixation fastness is low, causing color fading and color transfer'', etc. As there is a high possibility that secondary damage will occur due to cleaning work, we will generally accept cleaning. I can't. However, in response to strong requests from customers (such as mold growing on vintage items), and with full understanding that there is a risk of secondary damage, we have taken special measures such as: "Surface treatment" is available.

Although it cannot be denied that it is inferior to regular cleaning work in terms of dirt removal power and treatment effect, it is a special method to remove dirt as much as possible while minimizing damage to the product. Depending on the condition of the product, surface treatment may not be sufficient. We will make a judgment as to whether or not we can respond after seeing the actual item.

Normally, during cleaning work, items are soaked in an aqueous or oil-based solution, but severely deteriorated leather may not be able to withstand the agitation or the weight of the item containing moisture.

For this reason, when performing surface treatment, avoid soaking in various solvents, and instead use foamed detergent foam or a special lotion to remove stains. We will also treat the lining as much as possible if it is available. Rather than following a set procedure, we will decide on the details of the work based on the craftsman's judgment after looking at the condition of the product's leather, stitching, lining, etc.

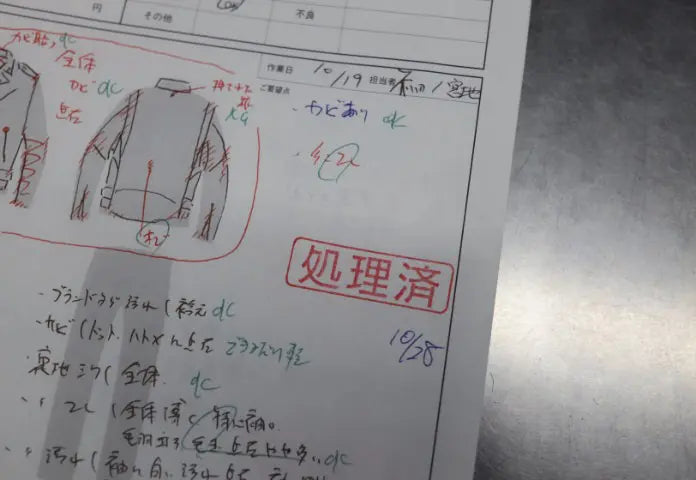

Final inspection

All products that have undergone preliminary inspection, washing, and drying are checked for dirt removal and changes in texture during the final inspection. Once the product has been successfully checked, a "processed" stamp will be stamped on the checklist and the product will be sent to the client.

If you request it in advance, we can also handle repairs such as zipper replacement and resizing in-house. Kadoya, which specializes in everything from manufacturing to repair, provides consistent services to maintain your favorite leather products.

STEP ①

press

Leave the wrinkles of aging due to use as much as possible, and iron it by hand to remove the wrinkles generated in the washing work, so that you use a medium -temperature press.

Depending on the condition of the leather, it may also lead to heat contraction, so it is a task to identify nerves.

STEP ②

check

After pressing, the products are checked in detail by comparing them with the checklist filled out during the preliminary inspection and the photographed images to check the degree of dirt removal and whether there are any changes in texture.

If there are any points that do not pass the check, we will reprocess the parts that meet the problems.

STEP ③

oil up

After the check is completed, the final oiling will be done. The leather has already been nourished internally, but this oil will add even more luster and shine. The basic rule is to apply oil thinly and widely. Among the requested products, we often see problems caused by applying too much oil.

Depending on the quality and color of the leather, it may not be possible to add oil to it, but don't worry, nutrition can be supplied during the washing process.

STEP ④

completion

This is a detailed checklist for each step of the work.

Once all processes have been completed, the product will be stamped with a "Processed" stamp on this checklist, and the refreshed leather jacket will be sent to the customer.

price list

| Item name | cleaning fee | Water repellent |

| leather jacket | From 8,800 yen | 2,750 yen |

| leather jumpsuit | From 14,300 yen | 3,300 yen |

| shearling coat down | From 11,000 yen | 2,750 yen |

| leather pants/skirts | Starting from 8,250 yen | 2,200 yen |

| leather vest | From 7,700 yen | 2,200 yen |

Cleaning orders/inquiries

- You can order from Refreza online or at a store near you.

- If you have any questions regarding cleaning, please email us. Please feel free to contact us.

Current delivery time: 2 months

Click here to order cleaning