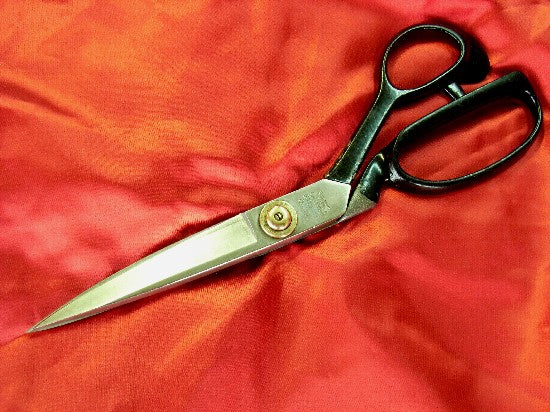

Rasa cutting scissors (cutting scissors)

One of the seven tools given to me by the president. cutting scissors.

These are large scissors that are mainly used for cutting fabrics.

The X-shaped type has a screw (fulcrum) between the blade and handle, and is the most common type with a wide range of applications.

It is also called ``Rasa cutting scissors''. The etymology of ``Rasa'' is a transliteration of the Portuguese word ``RAXA''.

Both ro and gau refer to thin silk fabrics, but they can also be used to cut thicker fabrics.

Is it a coined word? Or is it too sharp?

You can fix the blade in a half-open position and cut the fabric as if it were caught and torn.

It is said that it was originally imported around the time of the opening of the country in the Meiji period, but since then it has been adapted to fit the small hands of Japanese people.

It has been improved. Also, the manufacturing method is different.

While most European and American cutlery are made from a single piece of steel, Japanese cutlery is made from soft iron.

By combining hard steel (blade part), you can create subtle tones.

This is an inheritance of the excellent forging method seen in Japanese swords since the Heian period.

This manufacturing method produces a sharp edge and delicate feel.

If you don't swallow the feeling of breathing moving the two blades, you can use the scissors as you wish.

You cannot master it.

Having mastered this sense, each craftsman cuts the leather and fabric by himself at the factory.

There are various methods, some people use knives and cutters, while others use scissors.

Some people own several so they can use them depending on the material they are cutting.

In addition, the types are different, such as right-handed and right-handed, and left-handed and right-handed.

Normally, cutting scissors would not cut anything other than cloth, but at Kadoya,

Also used for cutting leather.

This style was created by a craftsman who used to be a tailor, but he changed his stage to a leather jacket shop.

It was created by incorporating unique methods and tools.

Some people take their blades to a sharpener, but most people sharpen them themselves.

This is also to increase work efficiency.

Although it is a little different from the usual format, it is done using tools that the person is familiar with.

The work is efficient, and above all, the attitude and quality of trying to make good products

No change.

What is most outstanding is the skill of a veteran craftsman who has gained experience as a tailor.

Fast and accurate cutting. In all directions.

Exactly Scissorhands.

【Nakamura】