To keep wearing for many years

It's almost time to change your clothes. .

It's almost time to change your clothes. .

Especially from summer to fall, we receive many inquiries about repairs and orders.

So this time we will talk about the repair of KA-GIJ(/SS) , the highest quality engineer boots that Kadoya is proud of.

I would like to briefly introduce the product along with a description of it.

First of all, engineer boots, as the name suggests, are a type of work boots and safety shoes made in the United States for use by engineers.

These boots are designed to protect your feet so you can work safely even in dangerous situations, and because of their high defensive performance, they are also loved by bikers whose undercarriage is easily damaged.

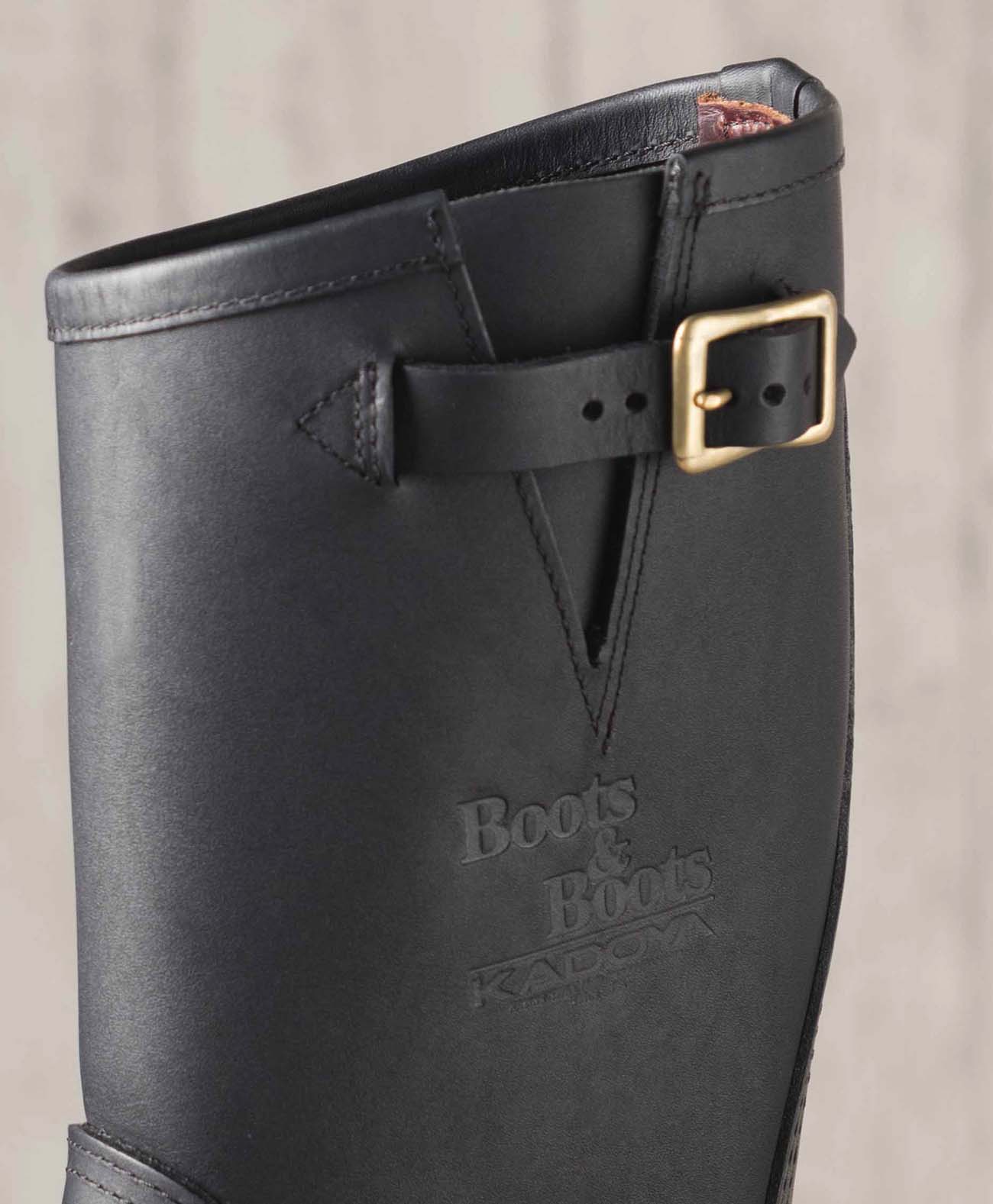

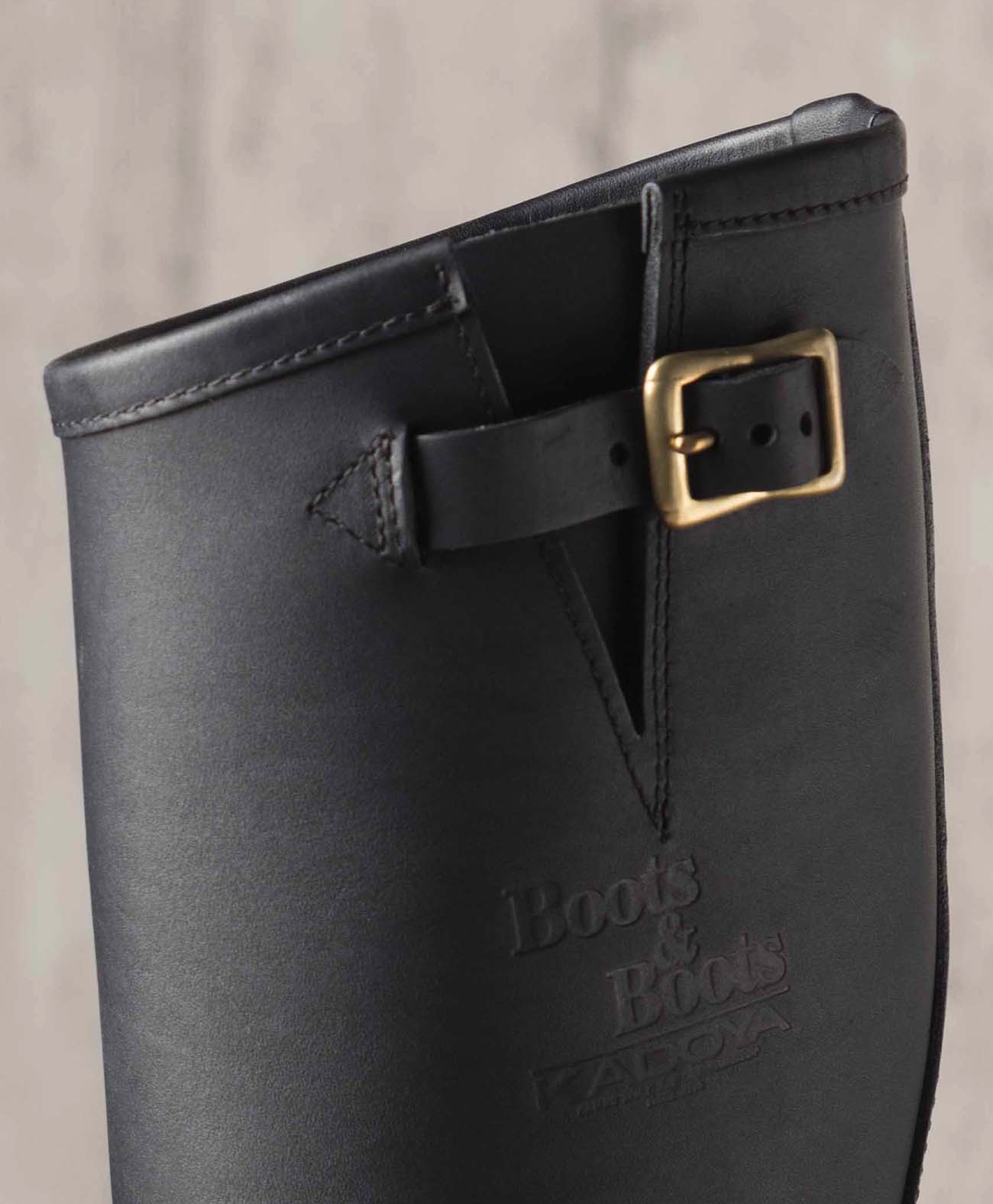

KA-GIJ (/SS) is made from European leather, which is known for its high quality.The extremely thick processed leather is soaked with plenty of oil, and the surface is coated with a thin coating to make it waterproof. It protects from scratches and external damage, ensuring sufficient durability.

The leather used is thick and heavy, but the shoe shape is tailored to Japanese feet, so as you wear them, you'll feel a fit that's much different from other shoes.

Regarding the sole, we have adopted Vibram's rugged-looking block pattern #1100 (KA-GIJ) and a flat sole that takes shift changes into consideration (KA-GIJ/SS) to ensure maneuverability such as ease of bending. These are engineer boots that have been carefully considered in every aspect.

↑【KA-GIJ】

↑【KA-GIJ/SS】

Next, let's talk about sole replacement.

This KA-GIJ series is made using the Norwegian method, which is sewn with two threads.

As shown in the photo, threads are sewn in places ① and ② , and although it is made using a very sturdy and time-consuming and complicated manufacturing method, it is not sewn all the way to the bottom of the sole. It is possible to change the sole at any time.

However, if the wear and deterioration affects the midsole, where the thread is sewn beyond the bottom sole, or the upper leather, repairing the midsole is risky and difficult. Masu.

Therefore, in order for you to wear your well-worn engineer boots for a longer period of time, we recommend replacing the soles a little earlier before the wear reaches the midsole and upper!

These are one of the boots that Kadoya staff have been using for many years, so why not give them a try?