papermaking

The process of making a single leather jacket can be divided into three main steps: cutting, sanding, and sewing.

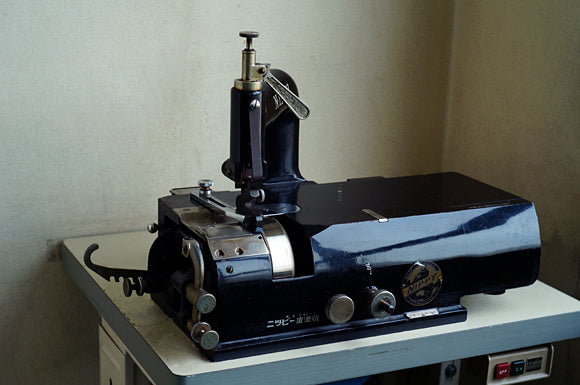

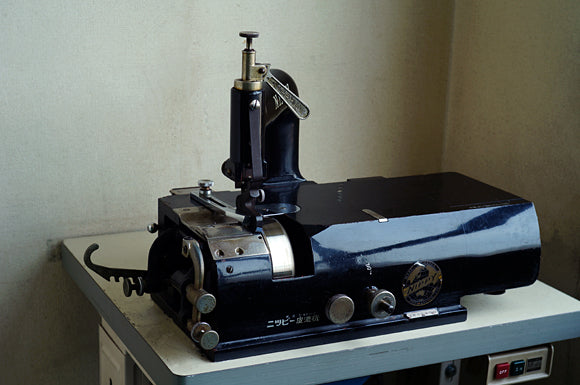

"Suki" is the process of using a leather skiving machine to reduce the thickness of a part of the leather or a whole part.

A "leather skiving machine" uses a barrel-shaped stone that rotates with the power of a motor to feed the leather, and a rotating blade that slices the leather into desired thickness.

It is probably only in the world of leather jackets that the process of ``sukii'' is used to make clothes.

The reason for papering is due to reasons on the manufacturer's side, such as the fact that if the fabric becomes too thick due to folding, it becomes impossible to sew or maintain thread tension, and also to improve product quality, such as improving comfort and adjusting strength balance. Although the sanding process is necessary for reasons related to the craftsmanship, the reason why leather is sanded in the first place is because leather is a material that can be sanded.

If you run a fabric made from thread through a leather skiving machine, the fibers will break and fall apart.

In recent years, thick denim pants of 20 ounces or more have become commonplace, but this denim fabric, which is thicker than thin leather, cannot be machined.

As a result, there is simply a six-fold difference in height between the one layer and the six layers, making it easier for friction to concentrate in pinpoint areas where the layer is thicker.

In the case of denim pants, you can enjoy the contrast of the fit, including the fading of the color, and that adds to its appeal, but with leather, you can adjust such things as you like.

There are three things we keep in mind when we make leather.

Strength balance, sewing efficiency, and nuances of finish.

Although leather can be made, there is a proportional relationship between strength and thickness, so there is a limit to how thin it can be made partially.

The flatter it is, the easier it will be to sew, but it will greatly affect the look of the finished product.

The ``shading'' created by the thickness is one of the unique charms of leather, and this is an area that should be taken care of, so even if not sanding leads to inefficient sewing, it is important to give priority to creating the expression of the leather jacket. Masu.

In the end, in most cases, straining will be kept to a minimum.

This ``suki'' process, which we usually take for granted, is a behind-the-scenes process that is difficult to convey to customers.

However, at Head Factory, we are very particular about whether we ``sake'' or not ``sweat'' our products, and the back-and-forth consideration of sukiyaki is nothing but the craftsman's love for the product.

This unique process of ``sukiki'', which adjusts the thickness of the material, is a very important process that creates the comfort and atmosphere of the product.

[Ichijima]