Layout

Manufacturing method used at Head Factory: “One piece per person”

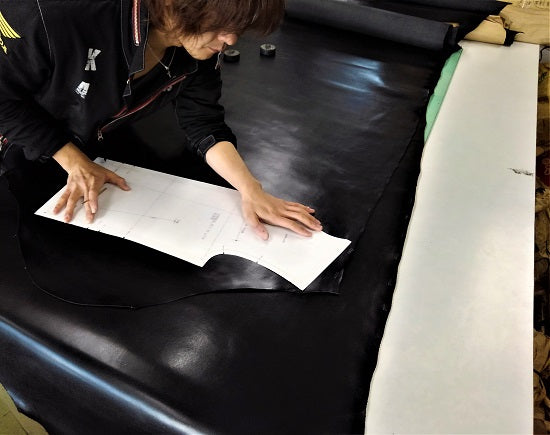

I would like to talk a little bit about the layout, which is the first step in the process.

First, we begin by rolling out a piece of leather and arranging the patterns for the parts.

We believe that this process is the most important process.

When it's new, it's beautiful and hard to tell, but as you use it, it starts to lose its shape, and there's a clear difference in the appearance of the left and right sides...

It's an expensive item and I wanted to keep using it for a long time, but I don't want to feel like this.

Therefore, we take advantage of the characteristics of the leather and lay out the parts of the product in the right place, assuming that it can be used for many years.

Overall and left/right balance. Places where good looks and strength are required. On the other hand, it is better to use the soft part here. Checking the direction of the leather's growth, the quality of the leather, and checking for scratches.

Depending on this process, no matter how carefully you sew the item, it may result in a disappointing finish.

By the way, when making a jacket, you will need two or more pieces of leather, and you will need to choose leathers with similar expressions. This is simply not possible in mass production.

Unusable parts can be removed during the layout stage, but scratches on the good parts can be added to places that are not visible from the front, such as padding areas or seam allowances.

Depending on the light and viewing angle, some scratches can be easily overlooked, so check again and again...

One of those seemingly invisible scratches is a biological wound that healed during life. It is the same as the scratches that everyone has on their body.

This is one of the original characteristics of leather that cannot be found in synthetic leather.

Because the materials are living things, no two pieces are the same, and we work on each piece one by one every day.

So the layout is not easy...